Cement boardwalk board

Cement boardwalk board

PRODUCT PRESENTATION

summary

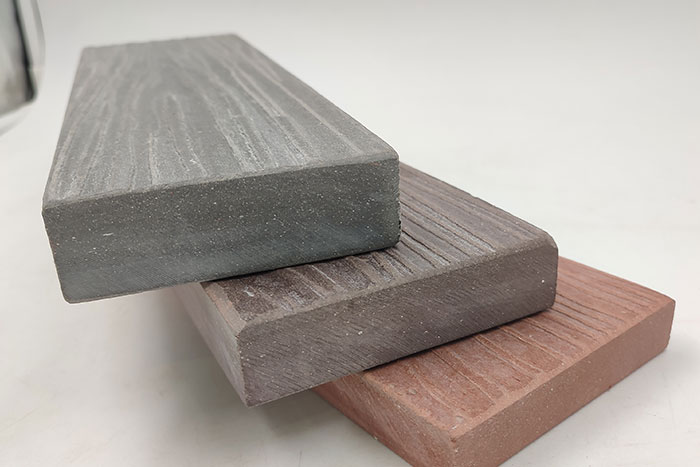

HUGO boardwalk board is made of silicate cement, reinforced fibers, and various mineral fillers as raw materials. After pulping, molding, pressurization, and steam curing, it is finally synthesized into an inorganic material board with simulated wood grain on the surface through advanced production technology; The board has superior properties such as anti slip and wear resistance, high pressure resistance, fire and moisture resistance, corrosion and moth resistance, and weather durability.

The HUGO boardwalk board is not only suitable for various boardwalk occasions in tourist attractions and residential areas, but also for small buildings attached to garden landscapes, artistic buildings in parks and private gardens, and external wall enclosures of various buildings. It is an ideal choice to replace traditional anti-corrosion wood and artificial plastic.

characteristic

Compared to traditional anti-corrosion wood and plastic wood panels:

1. The HUGO pallets are made of fiber-reinforced silicate materials during the production process, which have high impact resistance and extremely low manual maintenance costs;

2. Effectively resist damage from termites and other insects in harsh weather and outdoor environments;

3. It is not easily deformed under the exposure of sunlight and the erosion of rainwater, and has shown strong weather resistance through harsh freeze-thaw cycle tests;

4. It is a completely non combustible material that meets the A-level non combustible standard of GB8624, ensuring the fire safety of users. It plays the role of a "safety guard" under the landscape boardwalk.

Advantages of pallets:

1. Long service life: Board is an inorganic material that can effectively resist damage from termites and other insects. Under natural conditions, its effective service life is longer than that of wood, without the need for regular maintenance.

2. High strength weather resistance: The board has undergone 100 freeze-thaw cycles and 50 soaking drying cycles, exhibiting water resistance, acid resistance, alkali resistance, and weather resistance. It is suitable for use in harsh climate areas and has excellent impact resistance, making it safe for outdoor use.

4. Completely non combustible material: The combustion performance meets the A-level standard for non combustible materials in GB8624, ensuring the fire safety of users.

5. Green, energy-saving and environmentally friendly: The board is 100% asbestos free, free of toxic substances, meets national requirements for radioactive isotopes, and does not release harmful gases; When the lifespan ends, the board can still be recycled.

6. High cost-effectiveness: The total cost of using fiber cement pallets will be lower than using anti-corrosion wood, such as landscape pallets made of 24mm thick HUGO pallets, which have similar system performance to those made of 40mm thick anti-corrosion wood, but the overall cost plus later stages

Compared to maintenance costs, the cost-effectiveness of HUGO pallets will be higher.

7. Easy to process and install: In general pallet engineering use, the system structure can be basically maintained consistent with anti-corrosion wood, which can be nailed and drilled without the need for sanding and painting, and will not increase additional system costs.

8. Natural Art Appearance: During the production of boardwalks, the simulated wood grain and color are formed in one go, with prominent decorative effects. In addition, the whole body or surface is treated to various simulated wood colors, making it very suitable for landscape boardwalks that pursue natural, harmonious, and artistic effects.

Application scope

HUGO boardwalk board is the preferred material for modern outdoor garden architecture, scenic area engineering, and various high-quality building decoration projects. In addition to being suitable for various boardwalk occasions in tourist attractions and residential areas, it is also suitable for small buildings attached to garden landscapes, artistic buildings in parks and private gardens, and external wall enclosures of various buildings. It can effectively replace traditional anti-corrosion wood and plastic wood boards, creating a beautiful, economical, and A practical landscape environment.

TECHNICAL PARAMETERS

Product specifications

|

thickness |

width |

length |

|

15-30 mm |

1220mm |

2440mm |

|

|

|

|

Note: Customized cutting services can be provided according to the specific requirements of users.

Physical and mechanical properties and safety performance

|

standard |

detection result |

unit |

|

|

Density (in dry state) |

>1.5 |

one point five five |

g/cm ³ |

|

Water absorption rate |

≤ 20 |

seven point five |

% |

|

Moisture content |

≤ 10 |

three |

% |

|

Moisture expansion rate |

≤ 0.25 |

zero point zero five |

% |

|

Heat shrinkage rate |

≤ 0.5 |

one point three nine |

% |

|

Bending strength (transverse) |

≥ 12 |

twenty-three point six |

MPa |

|

Bending strength (longitudinal) |

≥ 10 |

nineteen point seven |

MPa |

|

Thermal conductivity coefficient |

≤ 0.35 |

zero point one six |

W/(m · k) |

|

radioactivity |

GB6566-2001 A1 Class |

Safe use |

- |

|

Flame resistance |

GB8624-A1 |

qualified |

- |

|

SGS/BS 476 Part 4 |

qualified |

||

|

Asbestos Content |

100% asbestos free |

Safe use |

- |